Can we double the efficiency of power plants with the condensation power process?

We THINK SO!

The condensation power process: ConPowP

We are a small team thinking "BIG" to make this planet a little better.

This website is about our first project that could revolutionize the way power plants generate electricity. We invite you to join us in a venture with exciting possibilities and projects.

We are open to ideas and suggestions and if you would like to contact us, you will find our email address at the bottom of the page.

About the condensation power process:

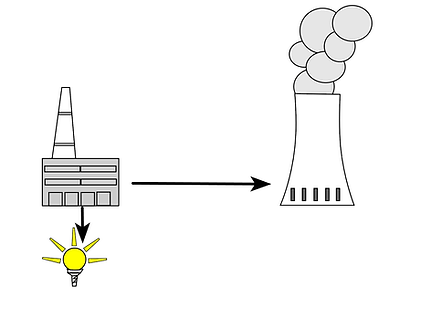

How can this invention be used to almost double the electricity output of power plants?

This is possible by heating an organic gas with the phase change (steam to liquid) of the water vapor produced by power plants and passing it through an electricity-generating ORC turbine. The condensing power process could be used in France, for example. France does not need to build any new nuclear power plants if it integrates the condensing power process into its existing power plants.

In contrast to previous ORC processes, this ORC turbine does not use the waste heat from gas-fired power plants and other industrial processes. Instead, it uses the condensation power process to generate kinetic and electrical energy.

Below is a video of an experimental setup showing the exact process. This is NOT some fancy new machine that creates energy out of nothing or from some exotic energy source. Instead, it shows that the phase change from vapor to liquid can harness organic gases to generate electricity.

The experimental setup is intended to be understood as a guide for replication.

When replicating the experiment, make sure that the heat losses through pipes etc. are the same on both sides.

Legal notice:

Any type of reproduction is the sole responsibility of the person who reproduces it. Liability for technical and economic success as well as for personal injury is 100% excluded by the publisher of these instructions. Reproduction is at your own risk. We expect all safety measures to be observed when rebuilding.

We accept no liability for any damage.

Further explanations:

The heat of condensation from water vapor can be used to vaporize and superheat propane.

This superheated gas can then be fed into a turbine to generate electricity.

The key to this process lies in the difference between the heat of condensation of the water vapor compared to the enthalpy of vaporization of the propane.

Propane requires less energy than water to turn it from liquid to gas and then it can be superheated to almost the same temperature.

When a liquid evaporates, it absorbs energy to change into the vapor phase.

This energy per mass is known as the enthalpy of vaporization. Separation energy and expansion energy are required during the transition from liquid to vapor.

Separation energy separates molecules so that they can move freely in the vapor, and expansion energy gives them space. The higher the heat of condensation of the water vapor and the lower the enthalpy of vaporization of the organic gas, the more thermal energy can be used to superheat the organic gas.

More superheat energy in the propane means more energy that can be converted into work output by the turbine. The conditions in the previous experimental setup already show that the organic gas can absorb enough heat energy to make its use in a turbine profitable. This energy is supplied as heat and released again during condensation. Evaporation and condensation are reversible and do not cause any losses when alternating. At thermal equilibrium, vapors contain both processes simultaneously. The amount of energy for evaporation and condensation at the same temperature is ultimately the same. As the temperature rises, both values decrease regardless of the type of gas. And above the critical point, they no longer exist.

Calculation example:

The enthalpy of vaporization/heat of condensation of water at 90°C is approx. 2278 kJ/kg. This means that 633 Wh of

heat are required to vaporize 1 kg of water at 90°C.

If 1 kg of water vapor condenses at 90°C in a heat exchanger, 633 Wh are also transferred.

In power plants, this condensation heat is also used to vaporize water, which is then released as clouds visible from afar.

In the case of propane, the enthalpy of vaporization/heat of condensation at 90ºC is approx. 133kJ per kg. This means that to vaporize one kg of propane at 90ºC, an energy input of 36.9 Wh is required. When one kg of propane evaporates in a heat exchanger, this 41.6 Wh is transferred.

633 / 36.9 = 17.1

By using the condensation heat of the water vapor, 17.1 kg of propane could be vaporized per kg of water vapor.

However, this propane vapor would also be saturated and therefore not usable for a turbine, as droplet impact would occur. In addition, the propane would have an unnecessarily high pressure of approx. 37.6 bar at the dew point.

It would therefore be better to vaporize the propane at 50°C less and then overheat it by 50°C.

The enthalpy of vaporization of propane at 40°C is 307 kJ, which corresponds to 85.3 Wh per kg. To this must be added a further 23.5 Wh per kg for the specific heat capacity/overheating as 1kg of propane can absorb approx.

0.47Wh per 1K/1°C.

This means that propane has 93% of the specific heat capacity of water vapor.

Together this results in 108.8 Wh per kg for superheated propane vapor around 50 K/°C.

633 / 108.8 = 5,8

By using the heat of condensation of the water vapor, 5.8 kg of propane per kg of water vapor could be vaporized and superheated by 50 K or °C. Only the superheated part of the propane vapor is converted into work output in the turbine by using its specific heat capacity from the superheating. In the example, the condensation heat of 633 Wh from 1 kg of steam without superheating generates around 5.8 kg of propane steam with around 494.7 Wh.

Around 136.3 Wh are then used to superheat the propane vapor.

In order to transfer the same heat capacity of 136.3 Wh to 1 kg of water vapor, it would have to be overheated by 267 K/°C, as 1 kg of water vapor can only absorb 0.51 Wh per K or °C of overheating.

136.3 / 0.51 = 267

Nuclear power plants operating at low temperatures of 350°C could certainly double their efficiency by additionally utilizing the heat of condensation. Engineers could also use other gases and create more favorable conditions. Large amounts of additional electricity could be generated with the depicted variant alone. This finding could lead to further innovations and even higher levels of efficiency.

Just imagine how much CO2 could be saved if all coal-fired power plants generated the same amount of electricity using half as much coal.

Application example: French nuclear power plants of recent design

The type N4 nuclear reactor is a 3rd generation water-cooled and light-water moderated pressurized water reactor developed by the former French company Framatome. It has a thermal output of 4250 MWth, a net electrical output of 1450 MWe and thus an efficiency of 34.1 %. (Source: Wikipedia/IAEA).

They therefore generate 65.9% waste heat. These reactors are used in 2 units each in Chooz and Civaux.

Each of these units can currently theoretically produce 12000GW/h per year. However, the units cannot operate at full load, particularly in the summer, as the 2800 MW of waste heat can often not be released. Utilization of the condensing power process could halve this load on the cooling system. This would enable these units to produce electricity more reliably. In France, the construction of 14 new power plant units is currently being planned, although the cooling problem requires new sites. The latest unit in Flammanville alone costs 12.7 billion euros. The Finnish EPR of the latest design also cost over 10 billion euros. Both construction projects were delayed by around a decade.

The newly planned nuclear reactors would become redundant if the old reactors generated twice as much electricity using the condensing power process.

Nuclear power supporters and opponents can win with this.

Thank you for your time and interest.

We are a small Team which shares a common Vision.

We belief that Power Plants in the whole world can run more efficiently with the condensation power process.

To us, the efficient and prudent use of our resources and environmentally friendly energy generation are our affair of the heart.

If you want to contact us.

Write to us at: info AT experiment2024.info

We ensure you that we will not give away your Email Adress to someone else. Your Email Adress is only for the contact between us and you.